Turnkey PCB assembly refers to a full-service approach where the manufacturer handles every stage of the printed circuit board production process — from component sourcing and PCB fabrication to assembly, testing, and delivery. This model eliminates the need for multiple vendors and complex coordination, giving businesses a streamlined, cost-effective, and efficient way to produce high-quality electronic boards.

In a turnkey setup, the manufacturer manages the entire supply chain. Engineers simply provide the design files — typically Gerber files, Bill of Materials (BOM), and assembly drawings — and the rest is taken care of by the service provider. This all-in-one process ensures faster lead times, consistent quality, and hassle-free production.

Turnkey PCB assembly has become the preferred option for startups, small businesses, and large-scale electronics manufacturers alike. It simplifies project management and enables faster time-to-market, especially for companies launching new products or scaling production.

The Process of Turnkey PCB Assembly

The turnkey PCB assembly process covers every step from concept to completion. It can be divided into several key stages that ensure seamless execution and high-quality results.

Design File Review

The process begins when engineers submit the necessary files, including Gerber data, BOM, and assembly instructions. The manufacturer reviews these files carefully to check for design errors, manufacturability issues, and potential cost optimisations before production begins.

Component Sourcing and Procurement

A major advantage of turnkey services is the inclusion of component sourcing. The manufacturer procures parts directly from verified global suppliers, ensuring authenticity and quality. This step saves clients from the complexities of dealing with multiple distributors and avoids issues like counterfeit or mismatched components.

PCB Fabrication

Once the materials are confirmed, the manufacturer begins the fabrication of the bare boards according to design specifications. This includes processes such as copper etching, drilling, plating, and solder mask application. Turnkey service providers maintain close quality control at this stage to ensure the boards meet design tolerances and performance standards.

Assembly Process

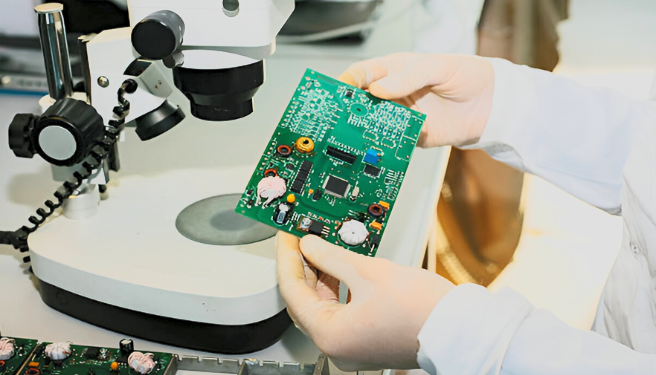

The next step involves assembling the PCBs using Surface Mount Technology (SMT), Through-Hole Technology (THT), or a combination of both. Components are placed on the board using automated pick-and-place machines, followed by reflow or wave soldering, depending on the design.

Testing and Inspection

Every turnkey PCB assembly undergoes rigorous inspection and testing to guarantee functionality and reliability. Common methods include Automated Optical Inspection (AOI), X-ray inspection for hidden joints, and functional testing based on customer requirements. These processes ensure that each board performs flawlessly before shipment.

Packaging and Delivery

Once testing is complete, the boards are cleaned, packed, and shipped to the client. The advantage of turnkey service is that the product arrives ready to use or integrate directly into the final system, reducing delays and simplifying the overall workflow.

Benefits of Turnkey PCB Assembly

The turnkey PCB assembly model provides numerous advantages that make it one of the most efficient and preferred solutions for modern electronics manufacturing.

Streamlined Process

With a single partner handling every stage, there is no need to coordinate between multiple suppliers. This integrated approach ensures better communication, fewer delays, and smoother execution from start to finish.

Reduced Lead Time

Since fabrication, assembly, and sourcing are managed under one roof, the overall production time is significantly reduced. This allows companies to bring their products to market faster — a crucial advantage in competitive industries.

Cost Efficiency

Turnkey PCB assembly eliminates the need for multiple procurement sources and reduces logistics costs. Manufacturers can also negotiate better component prices thanks to bulk purchasing and established supplier relationships.

Improved Quality Control

By centralising the entire process, quality assurance becomes more consistent. Turnkey manufacturers perform end-to-end inspections, ensuring each board meets both design and performance standards before delivery.

Simplified Project Management

With fewer touchpoints and one main point of contact, managing projects becomes easier. Clients can focus on product innovation and development instead of spending time on production coordination.

Flexibility and Scalability

Turnkey assembly supports both small prototype runs and large-scale production. Whether you are testing a new design or fulfilling mass orders, the same supplier can easily scale operations according to your needs.

Applications of Turnkey PCB Assembly

Turnkey PCB assembly is used across a wide range of industries that require precision, reliability, and efficiency in their electronic products.

- Consumer Electronics: Smartphones, home appliances, and wearables benefit from fast and cost-effective production.

- Medical Devices: Provides precision manufacturing for critical healthcare equipment and diagnostic tools.

- Aerospace and Defence: Ensures compliance with strict safety and performance standards.

- Automotive Electronics: Used in control units, sensors, and EV charging systems requiring consistent quality.

- Industrial Automation: Supports custom PCB solutions for automation, robotics, and sensor-based machinery.

Each of these industries relies heavily on turnkey assembly to deliver dependable, high-performance products with minimal production complexity.

Quality Assurance in Turnkey PCB Assembly

Quality control is a key element of turnkey PCB assembly, ensuring every board performs exactly as intended. Reputable manufacturers use advanced testing methods such as:

- AOI (Automated Optical Inspection): Detects soldering defects and component placement issues.

- X-Ray Inspection: Checks for hidden solder joints and internal connections.

- Functional Testing: Simulates real-world operation to verify the board’s performance.

Additionally, turnkey providers adhere to international standards such as ISO 9001, IPC-A-610, and RoHS compliance. This commitment ensures consistent quality and environmental responsibility.

Why Choose Turnkey PCB Assembly for Your Next Project

Opting for turnkey PCB assembly not only simplifies production but also enhances your overall efficiency and product reliability. With the entire process handled by a single, experienced provider, you can focus on innovation, design improvements, and market growth rather than managing multiple vendors or supply chains.

This approach is especially beneficial for startups and companies developing complex electronic products, where time, accuracy, and cost control are vital. By choosing turnkey solutions, you get complete visibility into the production process while maintaining flexibility and scalability.

Conclusion

Turnkey PCB assembly offers a complete, hassle-free, and efficient solution for all types of electronics production needs. By consolidating every step — from material sourcing and fabrication to assembly and testing — it ensures consistency, speed, and superior quality at every stage of manufacturing.

If you are looking for a trusted partner to handle your PCB production with precision and efficiency, working with reliable printed circuit board assembly suppliers is the best choice. A professional supplier can deliver end-to-end turnkey services tailored to your project requirements, ensuring high-quality PCBs that meet international standards and help you bring your innovative products to market faster.